VVAY Lighter: Durability and Longevity Test

This document outlines a comprehensive test plan for assessing the durability and longevity of a VVAY lighter. The goal is to simulate real-world use and determine the lighter's reliability under various conditions.

I. Test Parameters:

* Sample Size: 5 lighters (representative of production)

* Testing Environment: Controlled laboratory environment with consistent temperature and humidity

* Test Duration: 6 months

* Test Categories:

* Mechanical Durability:

* Drop Test (various heights, different surfaces)

* Impact Test (force applied to different areas)

* Flex Test (bending and twisting)

* Water Resistance Test (immersion, spray)

* Temperature Extremes Test (heat, cold)

* Functional Longevity:

* Ignition Rate (successful ignitions per attempt)

* Flame Duration (length of continuous flame)

* Fuel Efficiency (fuel consumption rate)

* Spark Reliability (consistent spark generation)

* Button Functionality (repeated use, pressure)

* Wind Resistance (flame stability in wind)

* Material Degradation:

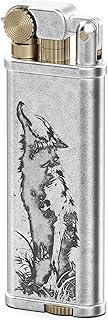

* Appearance (fading, discoloration, scratches)

* Material Integrity (cracking, warping, corrosion)

* Component Wear (spark wheel, flint, nozzle)

II. Test Procedures:

1. Mechanical Durability:

* Drop Test: Drop each lighter from various heights (1m, 2m, 3m) onto different surfaces (concrete, wood, carpet). Observe any damage, deformation, or component failure.

* Impact Test: Apply controlled force to specific areas of the lighter (top, bottom, sides) using a calibrated impact hammer. Measure the force required to cause damage and observe any structural changes.

* Flex Test: Apply bending and twisting forces to the lighter, simulating typical handling and stress. Observe any cracking, warping, or component failure.

* Water Resistance Test: Submerge each lighter in water (fresh and salt) for predetermined periods. Observe any water ingress, component malfunction, or corrosion.

* Temperature Extremes Test: Expose each lighter to extreme temperatures (high heat, extreme cold) for specified durations. Observe any material degradation, component failure, or performance impact.

2. Functional Longevity:

* Ignition Rate: Conduct a series of ignition attempts (hundreds per lighter) under various conditions (ambient temperature, humidity). Record the success rate and any ignition issues.

* Flame Duration: Measure the average duration of a continuous flame for each lighter, noting any variations.

* Fuel Efficiency: Measure the amount of fuel consumed over a predetermined time for each lighter under consistent usage conditions.

* Spark Reliability: Monitor the consistency and intensity of the spark generated by each lighter throughout the test period.

* Button Functionality: Perform a series of button presses (thousands per lighter) to assess its responsiveness, tactile feedback, and overall reliability.

* Wind Resistance: Test the flame stability of each lighter in a controlled wind environment (various wind speeds). Observe any flame flickering, blowouts, or performance issues.

3. Material Degradation:

* Appearance: Photograph the lighters regularly to document any changes in color, fading, scratches, or surface wear.

* Material Integrity: Inspect each lighter for cracking, warping, corrosion, or other material degradation over time.

* Component Wear: Observe any wear on the spark wheel, flint, nozzle, or other components. Document the extent of wear and any potential performance impact.

III. Data Analysis & Reporting:

* Record all test data in a detailed spreadsheet, including:

* Lighter identification number

* Test date and time

* Test category and sub-category

* Detailed observations and measurements

* Any failures or malfunctions

* Summarize the results in a comprehensive report, including:

* Overall performance of each lighter across all test categories

* Identification of any significant weaknesses or areas for improvement

* Statistical analysis of the data, where appropriate

* Recommendations for design modifications or material enhancements

IV. Conclusion:

This comprehensive test plan will provide valuable insights into the durability and longevity of the VVAY lighter. The results will inform product design and manufacturing decisions, ultimately leading to a more reliable and long-lasting product.